The eddy current separator is a machine mainly used in the recycling industry. Based on a principle discovered by a 19th-century French physicist, it enables extremely precise sorting between the various residues that make up the objects to be recycled and the non-ferrous metals they contain.

A tribute to Jean Bernard Leon Foucault

It is important to pay tribute to Jean Bernard Léon Foucault mentioned in this article, the currents to which he bequeathed his name. Born in 1819 and died in 1868, this French physicist and astronomer was extremely prolific during his short life.

He left a legacy of discoveries that had an impact on the whole world. In addition to currents, he also gave his name to the Foucault pendulum, which demonstrates the rotation of the earth around its axis; he was the first to determine the speed of light and invented the gyroscope.

What are eddy currents?

The eddy currents– eddy currents are currents created by an alternating magnetic field on a current-carrying material. Any variation in magnetic flux passing through a metal mass produces eddy currents. These electrical currents can be induced voluntarily or involuntarily.

In the case of a variable magnetic field in a metal plate – ferrous or non-ferrous – the phenomenon is natural. On the other hand, the magnetic field is artificially induced in the presence of the variable field of an electric coil.

These currents create a Joule effect, heating up the mass carrying the current. They can also be used as a braking force when they cause Laplace forces to appear, if the flux variation results from a displacement of the medium in front of a constant magnetic field.

Eddy currents in everyday life

Eddy currents are part of our everyday lives, and we use them in many applications.

Induction plates work by subjecting a stationary metal part to a high-frequency magnetic field. The eddy currents generated in the part cause Joule heating.

To brake trucks, a copper disc is attached to the wheel, next to a current-powered electromagnet. Eddy currents induce Laplace forces which slow down the movement, but this system does not replace conventional braking, as its effectiveness diminishes as the wheel slows down.

On the negative side, eddy currents cause overheating in transformers, as well as energy losses in electrical installations.

The eddy current separator

What is the purpose of the eddy current separator?

The eddy current separator separates non-ferrous metals from other materials. The elements to be sorted are conveyed in bulk onto a conveyor belt, which automatically separates and removes the non-ferrous metals.

These machines are mainly used by the recycling industry for waste processing. The incoming flow is treated by the eddy current separator and, at the end of the machine, a clean sorting process is obtained, enabling the various materials to be reused.

Generally speaking, the non-ferrous metal separator is used to recycle a wide variety of materials, such as glass, plastic, rubber, sand in aluminum foundries, shredded cables, automobile shredding lines, household waste, bottom ash…

It can also remove ferrous or weakly magnetic particles, e.g. from stainless steel, wired glass, etc.

Here are some examples of treatments:

- treatment of shaped wood and furniture: removal of copper hinges, nails, screws, handles, etc. ;

- recovery of door and window frames, handles and closing mechanisms;

- sorting of non-ferrous metals in residues after waste incineration ;

- treatment of household waste and recovery of metal parts from electronic equipment and cans, among others;

- removal of non-ferrous elements from ground glass, plastic, polyethylene, PVC, rubber, etc. ;

- separation of aluminium capsules in the glass or Nespresso recycling industry;

- recycling of carcasses and recovery of aluminum and its derivatives from aluminum shreds;

- purification of aluminum foundry sand ;

- recovery of copper, lead and aluminium from crushed cables ;

- battery processing of all kinds…

How does the eddy current separator work?

The residues to be treated are first crushed. In most cases, they still contain iron particles that need to be removed before passing through the eddy current separator. To this end, they are treated by an overband machine or magnetic drum, which attracts the steel particles and discharges them.

Next comes the eddy current separator, which separates non-ferrous metals from all other materials.

The function of the eddy current separator is to convey the bulk material to be treated onto its conveyor belt. The unit is fitted at the end with a multi-pole magnetic rotating drum, equipped with high-remanence neodymium permanent magnets. Driven at high speed, the magnetic field induces eddy currents in the conductive non-ferrous metals.

These currents create their own magnetic field, which opposes that of the pole wheel. In this way, inert residues continue their journey on the slatted conveyor belt, while non-ferrous residues are catapulted by the repulsive force and collected in a separate receptacle. A deflector is placed here to separate the two trajectories. It can be adjusted to suit the parts and materials to be processed.

In other words, for a fraction of a second, non-ferrous metals carrying an electric current become electromagnets with their own electromagnetic force. This is why non-ferrous metals, thanks to the speed of the conveyor belt that transports them, combined with magnetic repulsion, take a different trajectory to inert residues.

What influences the precision of non-ferrous metal separation?

Ferrous metals are more or less easy to separate. This depends on their electrical conductivity, their density and the ratio between the two. The better the electrical conductivity and the lower the density, the better the eddy currents will be able to separate a material.

Electrical conductivity

Electrical conductivity is calculated in siemens per meter and symbolized by the Greek letter sigma: σ. In descending order, it ranges from silver at 62.1 σ, through copper, gold, zinc, aluminum, magnesium, brass, cadmium, platinum, tin, chromium, bronze, lead and titanium, to stainless steel at 1.4 σ.

Density

Density determines the ease with which they can be catapulted off the conveyor, as it involves the force of gravity. The eddy currents of the magnetic roller must generate sufficient force to overcome this force of gravity.

Optimize your recycling operations now!

Recycling plays an increasingly central role in our society.

Faced with growing waste volumes, it is crucial for manufacturers to equip

with high-performance eddy current separators.

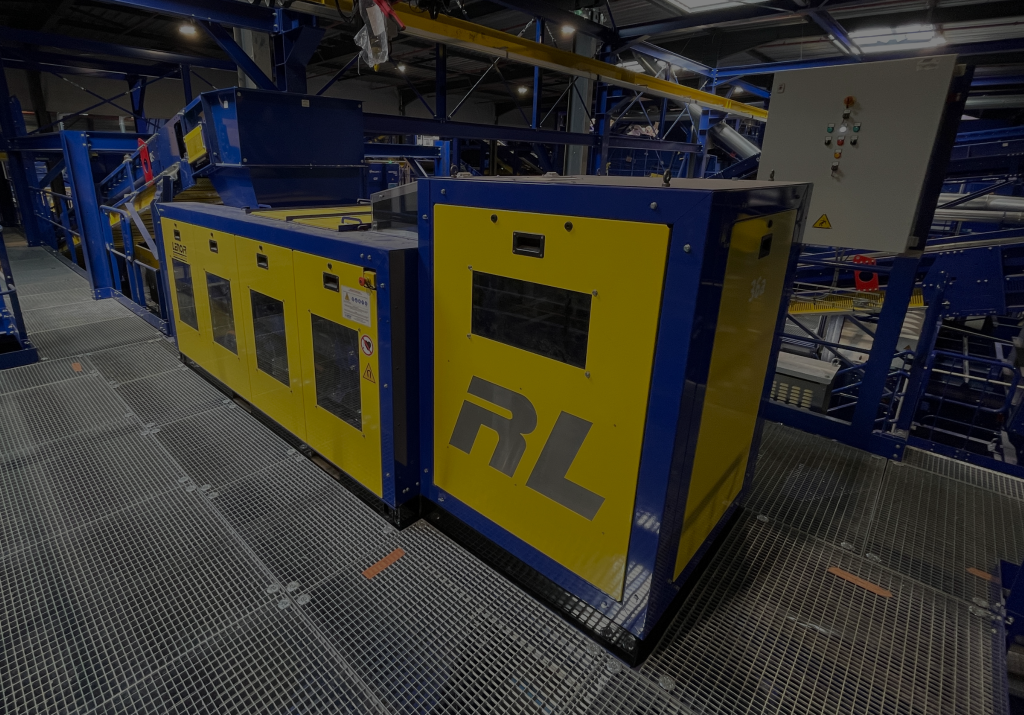

At LENOIR-MEC, we’ve been designing and installing these technologies for years, equipping

more than 80% of sorting centers in France.