Electro-permanent lifting magnets are transforming industrial handling thanks to their hybrid technology. These magnetic systems combine energy efficiency, enhanced safety and operational autonomy to transform your handling operations.

Electropermanent Lifting Magnet: Definition and Functioning

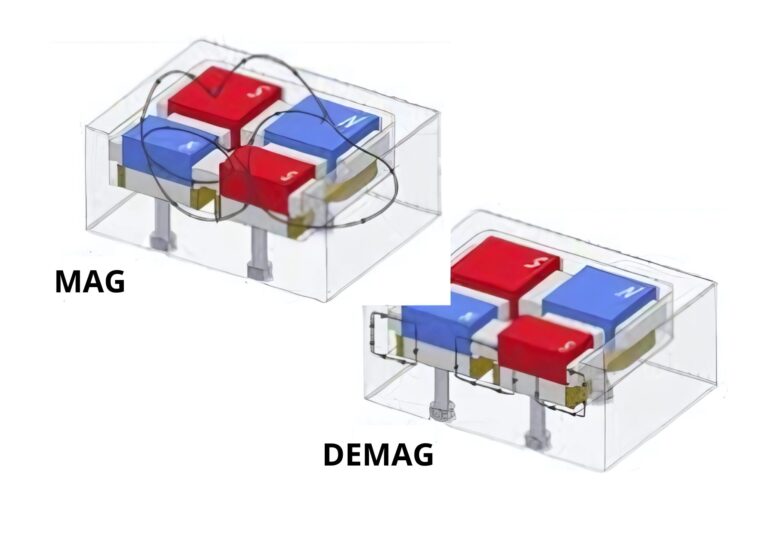

An electro-permanent lifting magnet is a hybrid magnetic device that combines permanent magnets with electrically controlled coils. Unlike conventional electromagnets, this lifting equipment only requires electricity to activate and deactivate the magnetic field. They maintain their lifting force thanks to integrated permanent magnets.

Electropermanent magnet technology and components

Electro-permanent magnet technology relies on several essential components:

- Neodymium permanent magnets: Provide the main magnetic force

- Circuit électrique de commutation : Permet l’inversion du champ magnétique

- Intelligent control system: Manages precise activation/deactivation

- Reinforced protective casing: Withstands demanding industrial environments

- Batterie longue durée : Autonomie jusqu’à 1000 cycles par charge

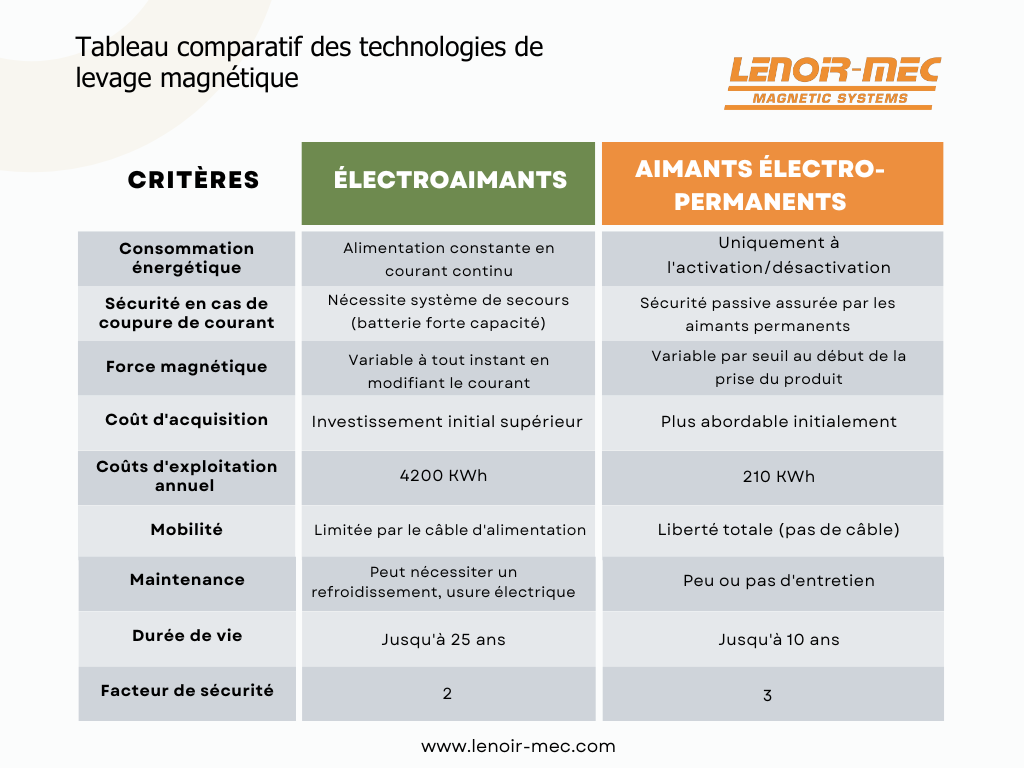

Permanent Magnet vs Electromagnet: Complete Comparison

Each magnetic technology offers specific advantages depending on the intended industrial handling application. This comparison will help you identify the optimal solution for your magnetic lifting needs.

Avantages spécifiques des électroaimants

Les électroaimants excellent dans plusieurs domaines d’application grâce à :

- Magnetic field dynamically controllable by a DC drive

- Can generate a magnetic field with great depth (useful for picking up several stacked sheets of metal)

- Exceptional impact resistance

- Ideal for difficult applications on hot products (>150°C)

Specific advantages of permanent electromagnets

Permanent electromagnets offer considerable advantages for industrial handling:

- Energy efficiency: 95% savings compared to conventional electromagnets

- Enhanced safety: automatic load retention even in the event of a power failure

- Operational flexibility: operation without continuous power supply

Once activated, the magnet holds the load thanks to its permanent components, ensuring passive safety without continuous power consumption.

Identified Limitations

- Electromagnets: continuous power consumption, risk of overheating, need for permanent power supply.

- Electro-permanent: shallower magnetic field, reduced efficiency above 80°C, less adaptable to frequent variations.

Recommendations for Use According to Application

Electromagnets are preferable for:

Electromagnets are your best ally when handling materials at high temperatures or in extreme conditions. If you work with steel, which can reach temperatures of up to 600°C, electromagnets will provide the magnetic performance needed to hold your load.

It is also the recommended choice when you cannot guarantee direct contact with your parts: presence of paint, oxidation, impurities or significant working distance (air gap greater than 2-3 mm). Overhead travelling cranes and fixed cranes particularly benefit from this technology.

Examples of applications: steel industry, foundries, demolition cranes, sorting conveyors, handling of uncleaned raw parts, unloading of raw materials.

Choose electro-permanent magnets for:

Electro-permanent magnets excel when you are looking for energy efficiency and working on finished or semi-finished parts at room temperature. If your work cycles involve holding metal sheets for long periods of time (machining, assembly, storage), this technology will save you up to 95% in energy costs, as it only consumes power when activated and deactivated.

Direct contact with clean surfaces maximises its magnetic efficiency. Mobile spreader beams and autonomous lifting equipment are particularly suited to this technology.

Examples of applications: handling finished sheet metal, precision assembly, industrial robotics, portable maintenance equipment, lifting machined metal parts.

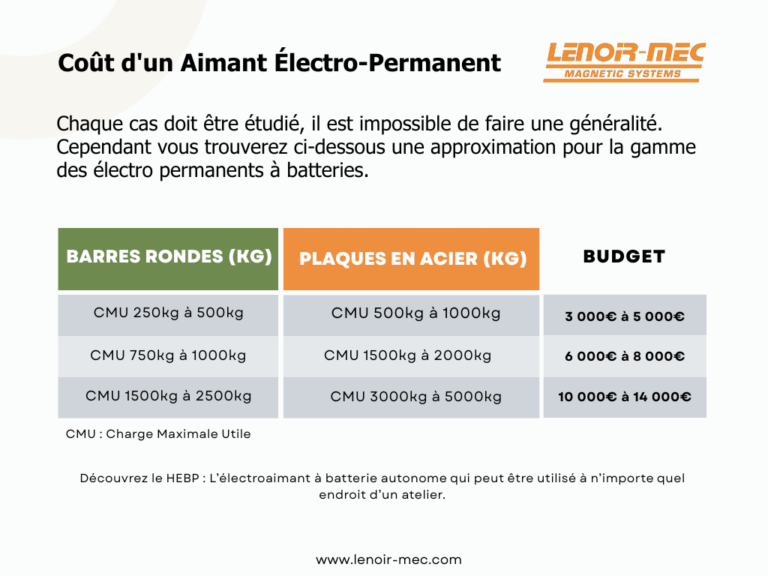

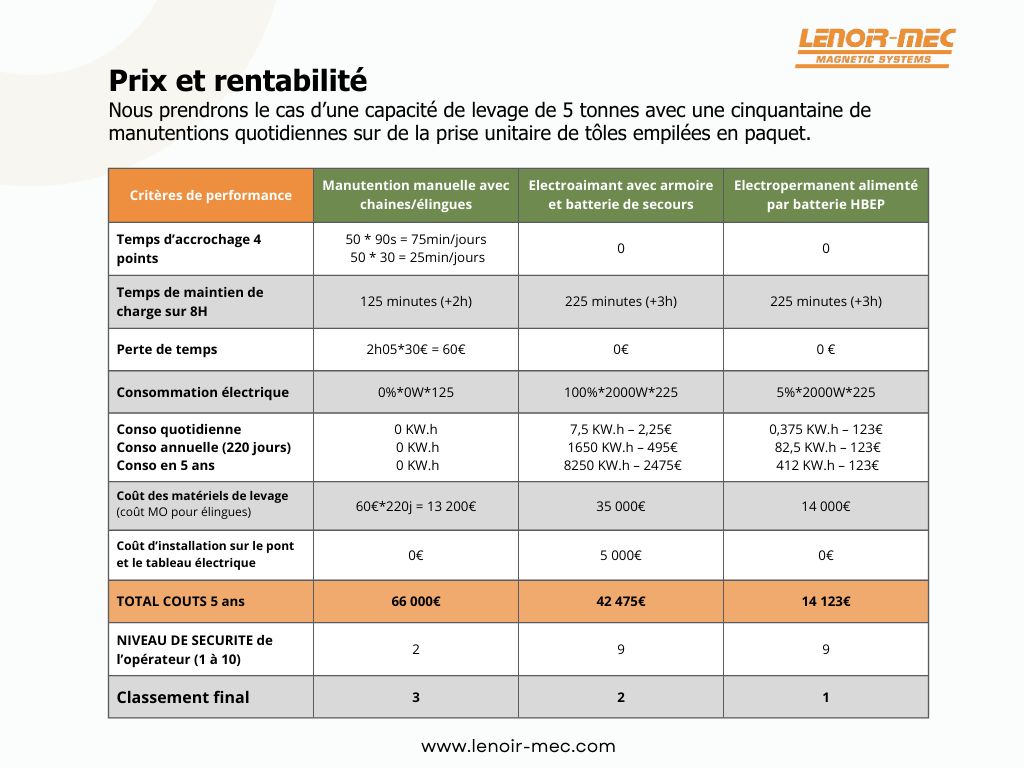

Return on investment

Several scenarios are possible:

You are using chains or slings:

Handling is slow because you have to attach four points, move out of the area and then move the load with your bridge or jib. You then have to detach it manually. Not only is there a risk of pinching or the load falling, but you also have to check the condition of the slings.

You are using an electromagnet for lifting:

Due to its nature, which requires a constant power supply, your bridge must be equipped with a dedicated electrical cabinet, a reel, and backup batteries that kick in in the event of a power cut. Installation costs are an important factor to consider in addition to the cost of the equipment and its power consumption.

You are using an electro-permanent solution:

This technology requires a pulse to magnetise. The HBEP device is self-contained in every sense of the word and can be recharged from a standard socket (220 Vac) between once a week and once a month, depending on how often you use it.

Find out how much you could save!

Maintenance of Electromagnets

Simplified preventive maintenance

Electro-permanent magnets require minimal maintenance with periodic checks:

- Visual inspection

- Regular cleaning of magnetic contact surfaces (under the magnet)

- Battery charge check (built-in LED indicator) for HBEP and HBEPP models

- Annual regulatory inspection in accordance with standard EN 13155 for the CMU (with a coefficient of 3)

Lifespan and reliability

An electro-permanent magnet de qualité industrielle peut fonctionner plus de 10 ans avec un entretien approprié. Les modèles HBEP permettent plus de 1000 cycles avec une seule charge, et leur conception robuste résiste aux environnements industriels exigeants. Periodic checks ensure that magnetic performance is maintained.

FAQ: Electro-permanent lifting magnets

What is the difference between an electromagnet and a permanent magnet?

The electromagnet requires a continuous electric current to maintain its magnetic force. As soon as the power is cut off, the load is released. The permanent electromagnet, on the other hand, only consumes electricity when it is activated and deactivated. Once activated, it maintains the load thanks to its integrated permanent magnets, even without a power supply.

Can these two technologies be used in the same installation?

Absolutely! Many industrial workshops intelligently combine the two technologies depending on the workstation: electromagnets for fixed production lines with a secure power supply, and permanent electromagnets for mobile workstations, self-propelled cranes or environments without a guaranteed continuous power supply. Overhead cranes can therefore be equipped with both systems as required.

What happens in the event of a power cut?

This is where the major advantage of the permanent electromagnet lies: it automatically retains the load thanks to its passive safety feature. With a traditional electromagnet, the load can be released instantly if no backup safety system is in place.

What is the lifespan of an electro-permanent magnet?

A high-quality permanent electromagnet can operate for over 10 years with proper maintenance. Recent HBEP models allow for over 1,000 cycles on a single charge, and their robust design can withstand demanding industrial environments.

Can these magnets be used on hot parts?

Permanent electromagnets lose their properties above 80°C. For high-temperature applications (up to 600°C), electromagnets are preferable.

Conclusion: Choosing Between Electromagnets and Permanent Electromagnets

Both technologies can coexist in the same industrial facility, each optimising specific workstations. The shift towards electro-permanent magnets is part of a drive towards greater energy efficiency and safety, without systematically replacing electromagnets in their areas of excellence.

A customised technical analysis remains essential to determine the optimal solution according to your specific operational constraints, whether for fixed or mobile lifting equipment.

Make the right choice with our experts

This article helps you better understand electro-permanent magnet technologies, but our experts travel throughout the United Kingdom and abroad to analyse your specific magnetic lifting needs and recommend the optimal magnetic lifting solution for your industrial application.

A Global Leader in Industrial Magnetism

With nearly 80 years of expertise in developing customised industrial magnetic applications, LENOIR-MEC is your trusted partner for electro-permanent magnetic lifting solutions.

Contact our team of experts for a personalised demonstration and receive a free technical audit tailored to your industrial handling needs.