Fixed permanent magnet, mobile permanent magnet, or electromagnetic magnet?

The choice of an overband affects your sorting efficiency, energy costs, and maintenance. Each technology responds to specific constraints: stable or variable flow, fixed or mobile installation, need for control or desire for autonomy. Lenoir-Mec offers you a clear overview of the three main options on the market to help you identify the one that truly corresponds to your production configuration.

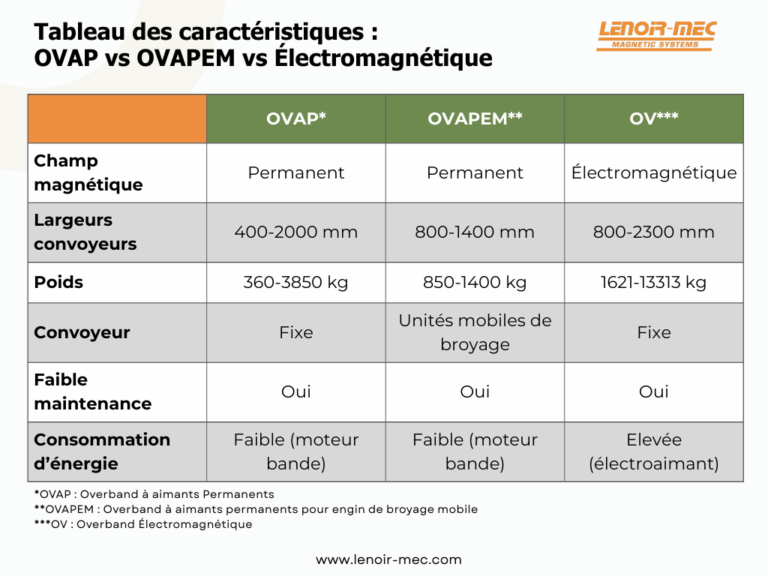

How to use this table of characteristics: OVAP vs. OVAPEM vs. Electromagnetic

These three technologies fulfill the same mission: removing ferromagnetic contaminants from your product. The difference lies in how they achieve this and the constraints imposed by your installation.

The selection process begins with your operating constraints. The width of your conveyor determines which models are compatible. The weight of the magnetic separator is also a decisive factor: suspending 13 tons (maximum OV) is completely different from suspending 1.4 tons (OVAP). Your metal structure must be able to bear this load; this is a technical requirement.

Once these constraints have been validated, examine your energy and operational context. Permanent magnets (OVAP) generate their magnetic field without consuming electricity, 24 hours a day, without variation. Electromagnets (OV), on the other hand, require a continuous power supply, but deliver greater separation power in return: you can choose between permanent magnets and electromagnets.

The table summarizes these trade-offs: compatible dimensions? Acceptable weight? Available energy or search for autonomy? Each “no” or “yes” answer eliminates or confirms, until you choose the technology that suits your needs.

Overband à aimants Permanents (OVAP) : La Référence pour convoyeurs Fixes

OVAP is the magnetic separator for fixed lines: aggregate quarries, mines and quarries, inert waste recycling, agri-food industries, sawmills.

Key features: The permanent magnet overband Low power consumption (belt drive motor). Thanks to its permanent magnets (ferrite or neodymium), it operates without a power supply, 24 hours a day, 365 days a year. Its integrated self-cleaning system removes captured ferromagnetic materials without human intervention. With a speed of convoyeur Between 0.5 and 3 m/s, it adapts to most production lines. It requires virtually no maintenance.

The flexible mounting (transversely or longitudinally to the pier) allows it to be easily integrated into a variety of configurations, even on existing lines, while ensuring continuous and regular extraction of ferrous metals.

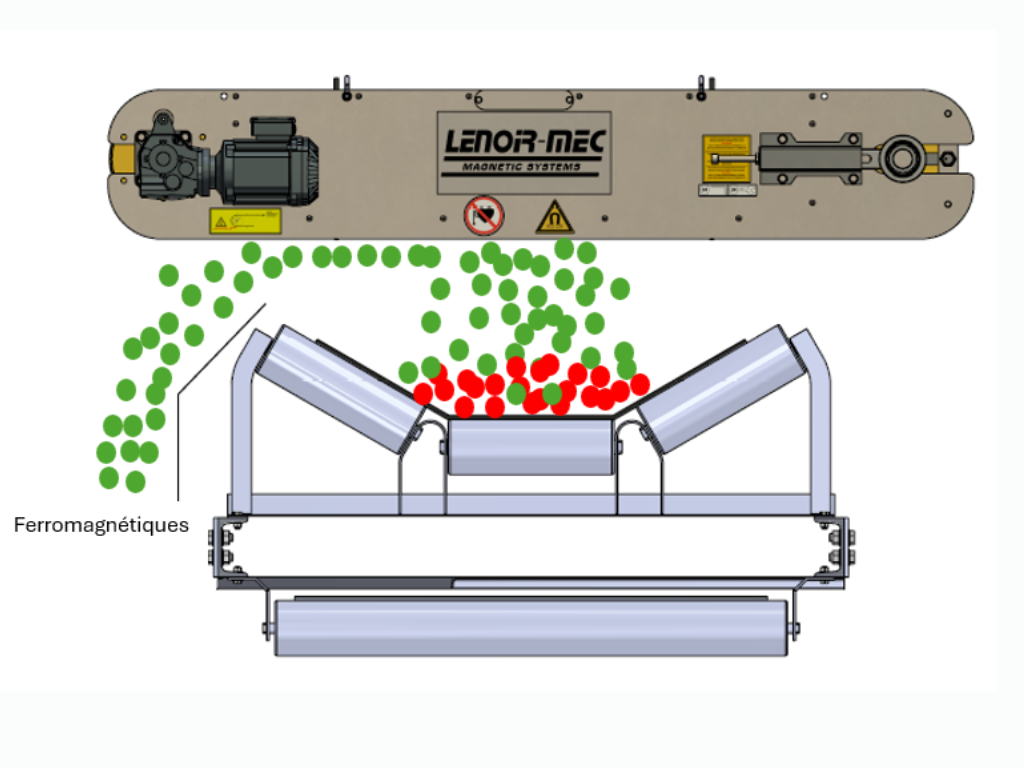

Operation: Permanent magnets generate a constant magnetic field that attracts ferromagnetic contaminants circulating under the separator. These pollutants are pressed against the integrated conveyor belt, then discharged into a dumping area, far from the main flow.

Case study: Aggregate quarry in Auvergne-Rhône-Alpes

Context: A quarry producing aggregates was experiencing recurring problems with ferrous contamination (pieces of reinforcement bars, bolts), causing damage to secondary crushers and resulting in significant costs for repairs and maintenance.

Solution: Installation of an OVAP above the crusher feed line, in accordance with the product characteristics.

The production manager says: “We installed the OVAP in June, and since then, we’ve forgotten all about it. It runs, it does its job, period. No more emergency shutdowns, no more stress, no more breakdowns. A significant increase in profitability.”

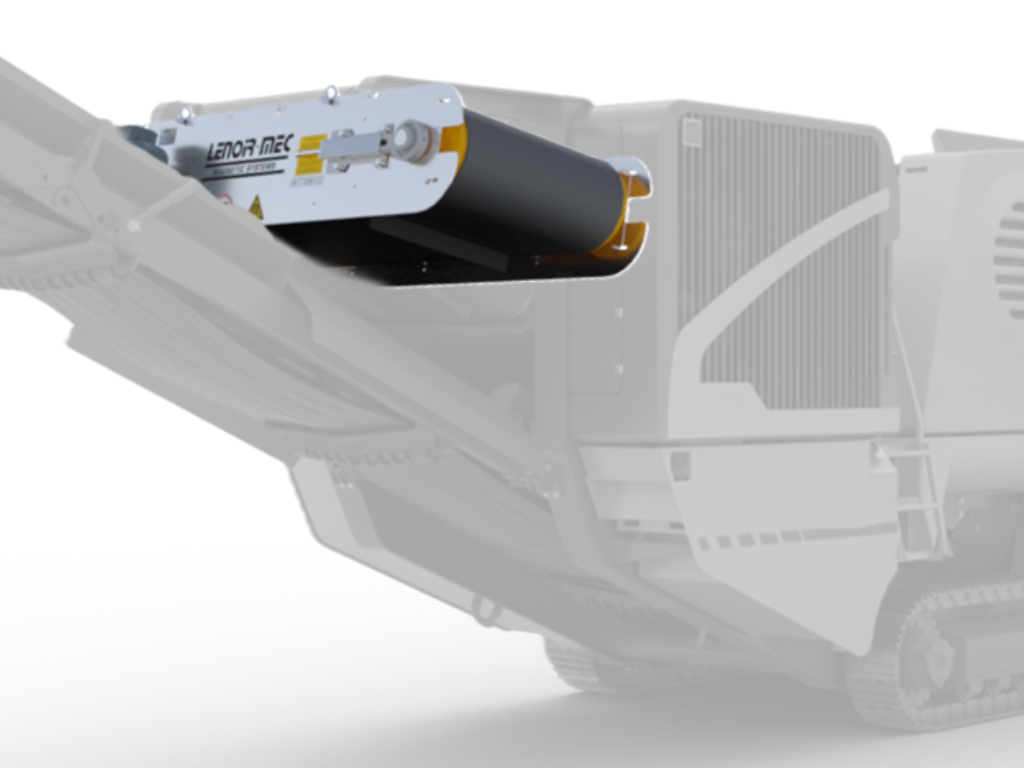

Overband with permanent magnets for mobile crushing equipment mobile

The OVAPEM is a separator designed for mobile crushing equipment: mines and quarries with mobile installations (tracked crushers), demolition sites, and mobile forestry operations.

Key features : Designed for installation on mobile equipment. OVAPEM offers all the advantages of permanent magnets (low maintenance). Its robust and lightweight design incorporates powerful permanent magnets. The self-cleaning system operates continuously and guarantees consistent performance.

Operation Technically, OVAPEM is similar to the OVAP principle: permanent magnets and continuous removal of pollutants. OVAPEM easily adapts to the different sizes of your mobile equipment.

Case study: Mines and quarries in the Grand Est region

Context: A company operates in a quarry with a mobile crusher to recover minerals. Ferromagnetic materials (scrap metal, nails, rebar) degraded the quality of the recycled minerals and complicated their resale.

Solution: Integration of an OVAPEM on the mobile crusher to eliminate pollutants.

The technical manager explains: “OVAPEM has transformed our process: the ores are cleaner and we are finally obtaining a product that can be sold on the market.”

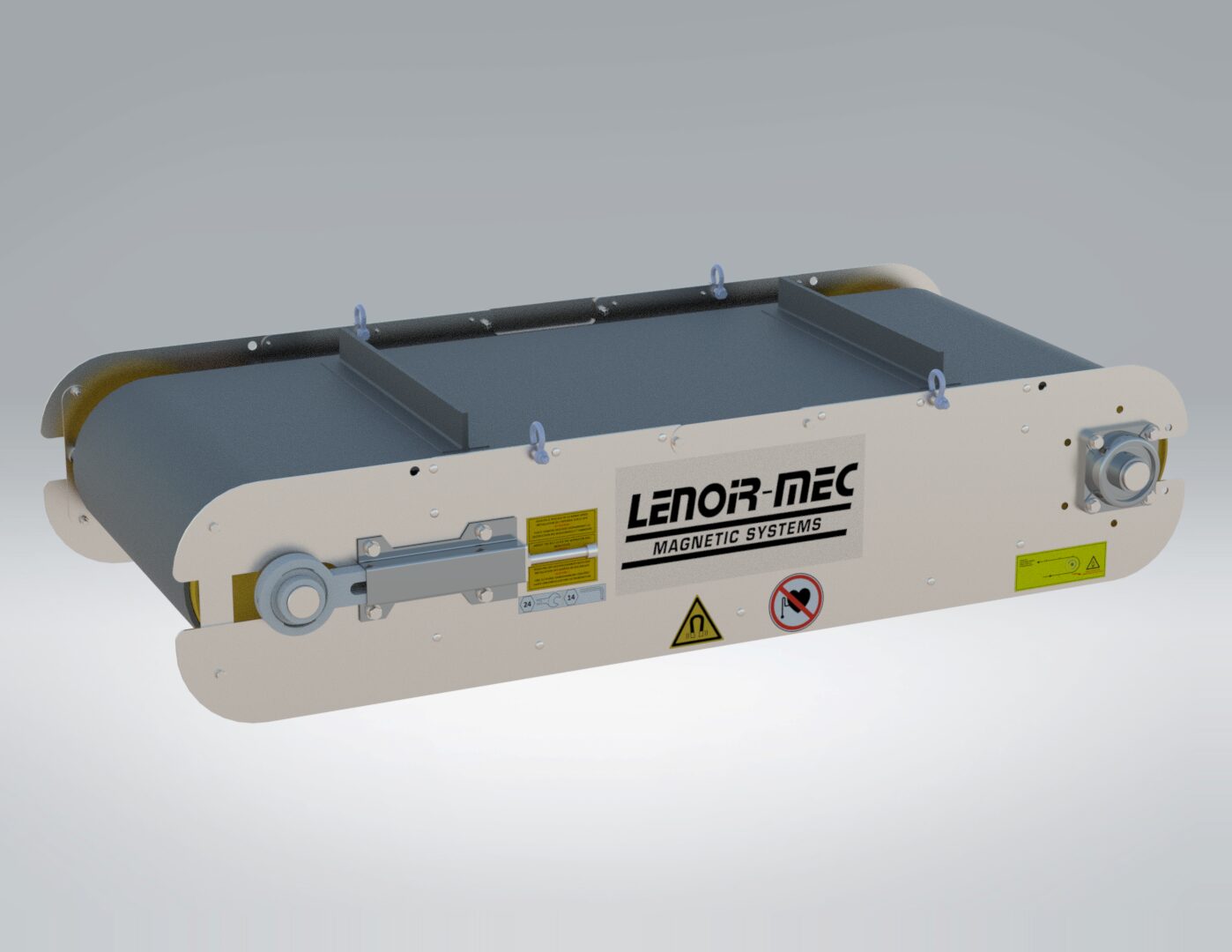

Electromagnetic Overband: The benchmark for separation in demanding environments

The electromagnetic overband is designed for demanding industrial applications: RDF (Refuse Derived Fuel) sorting centers, mines and quarries, cement plants, industrial and household waste recycling and recovery, the wood industry, and the agri-food industry.

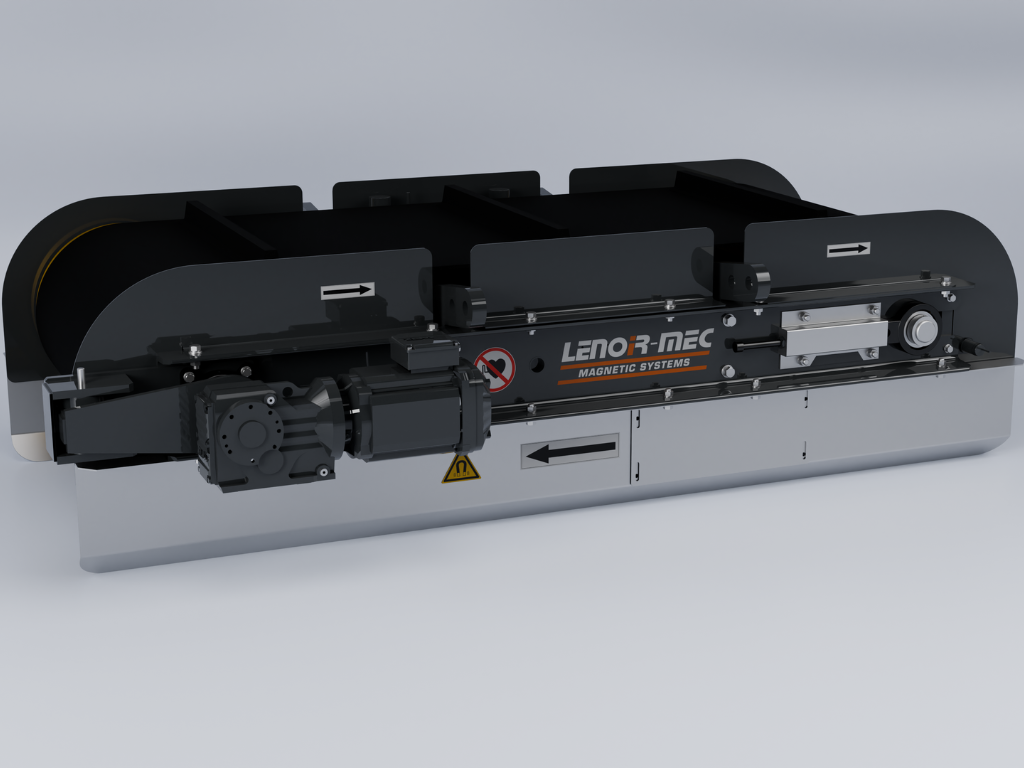

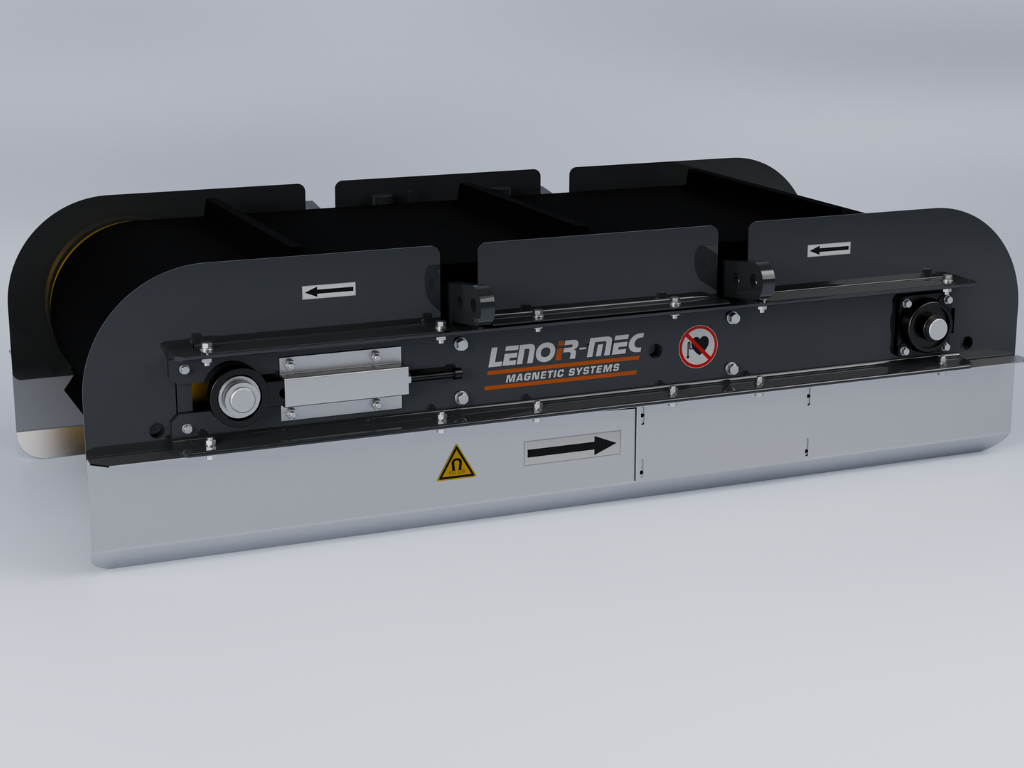

Key features: The assembly is based on a rectangular electromagnet suspended by four sturdy double-drilled lugs, supported by two U-shaped profiles that hold the drums mounted on bearings. The through-shaft gear motor ensures its operation. It is completed by an endless conveyor belt equipped with stainless steel clips.

Operation: Electromagnetic overbands generate a deep magnetic field, ideal for processing flows with high material thicknesses. Installed above or at the end of a conveyor, the device effectively attracts and extracts ferrous pollutants. They are automatically removed via the integrated conveyor belt. To further optimize separation, it can be coupled with a metal detector. The equipment can also be deactivated if necessary for maintenance and cleaning operations.

Case study: CSR sorting center in Île-de-France

Context: At a CSR sorting center in the Paris region, processing mixed waste required a solution capable of handling a higher product density.

Solution To meet this requirement, an electromagnetic overband was installed in a transverse configuration, combined with a metal detector to enhance sorting efficiency. This configuration enabled ferrous materials to be automatically removed and the process to be optimized.

The technical director emphasizes: “The overband has significantly improved the efficiency of our line. We have gained in safety and improved our production. And with the contract With Lenoir-Mec’s annual periodic inspection (SAV), we have gained peace of mind.

In summary

Overband with permanent magnets:

Standalone separator operating 24/7 without power consumption, reliable with minimal maintenance.

Overband with permanent magnets

for mobile equipment:

Compact and robust separator, designed for mobile machinery, ensuring continuous separation.

Overband

Electromagnetic:

Recommended for applications requiring a deep magnetic field for thick flux.

FAQ: Overband magnet

What is the difference between an electromagnet and a permanent magnet?

The permanent overband uses magnets that generate a constant force without electricity (0 kW for magnetization). The electromagnetic requires 2-15 kW continuously to power the coils. In summary: If your product is stable and not very dense: permanent. If you want more power: electromagnetic.

Can these two technologies be used in the same installation?

OVAP or OVAPEM: which one should you choose?

Permanent magnet overband (OVAP): Fixed installations

Permanent magnet overband for mobile crushing equipment: Mobile equipment only

-

Lightweight design 120–450 kg (−30 to −40%)

-

Stainless steel frame and components

-

Vibration resistance and 30° tilt

Identical magnetic performance, only the mechanical design differs. If your equipment is mobile, OVAPEM is mandatory to comply with weight restrictions.

Can we install an overband on an existing conveyor?

Yes, integration into an existing site is common.

Checkpoints:

- Structural strength: must support 150-1400 kg depending on model

- Available space: height + ferrous waste chute

- Power supply: three-phase 400V panel for gear motor

The double-drilled mounting lugs on Lenoir-Mec overbands make it easy to adapt to different configurations.

What happens in the event of a power cut?

This is where the major advantage of the permanent electromagnet lies: it automatically retains the load thanks to its passive safety feature. With a traditional electromagnet, the load can be released instantly if no backup safety system is in place.

Which metals are captured?

Only ferromagnetic materials:

-

Iron, steel, cast iron, ferrous alloys

Does NOT capture:

-

Aluminum, copper, brass, bronze

-

Austenitic stainless steel: These metals require other technologies (eddy current separators).

Conclusion: Choosing Between Electromagnets and Permanent Electromagnets

The choice of an overband is not limited to technical criteria: it must precisely meet your field constraints and performance objectives.

- For a stand-alone, cost-effective solution, the OVAP stands out for its very low energy consumption. Equipped with permanent magnets (ferrite or neodymium), it operates continuously, all year round, while its self-cleaning system removes ferrous materials without human intervention, with maintenance reduced to a minimum.

- If your business requires mobility, OVAPEM is designed for seamless integration into mobile equipment, while retaining the advantages of permanent magnets.

- For increased power and control, the OV offers a deep magnetic field, ideal for thick flows, with the option of being deactivated for maintenance or cleaning.

At Lenoir-Mec, we guide you toward the most suitable solution thanks to a fully customized approach:

site analysis, sizing, commissioning, responsive monitoring, and regular checks.

Would you like help making your choice? Our experts will analyze your configuration free of charge and guide you toward the most suitable equipment.